How much does searching for goods across the warehouse cost you?

Too much time wasted searching for items

When items aren't clearly located, pickers lose hours every day walking the warehouse.

Wrong deliveries and complaints

Without automated checks, wrong items or quantities can easily be shipped.

Dependence on one or two people

When the people who 'know where everything is' leave, work stops. WMS ensures everyone knows where things are.

Just 5 minutes searching per order × 20 orders per day = 100 minutes daily. That's more than 4 working days per month just for searching.

How Sensiteh WMS digitizes the warehouse

ERP sends data to WMS

Delivery notes, orders and receipts automatically appear in the WMS.

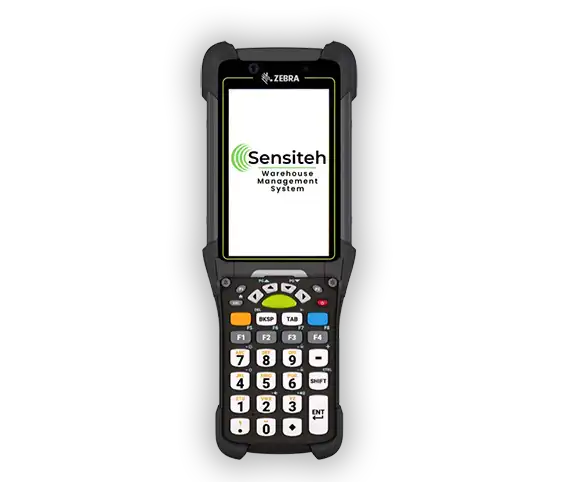

Warehouse worker scans items

The terminal shows where the item is located and verifies the scanned product's correctness.

Data is sent back to the ERP

WMS updates item status and returns data to the ERP for further processing.

When every item knows its place. See Sensiteh WMS in action.

Faster order processing

The warehouse worker sees exactly what needs to be issued and where each item is located.

Correct deliveries

The system prevents mistakes — an item cannot be issued if it is not correct.

Real-time monitoring

The warehouse manager sees all processes — what has been received, shipped and who is handling which document.

ERP integration

Data synchronizes automatically without manual entry and duplication.

Full visibility of item movements

From receipt to dispatch you know where every item is and who processed it.

Easy to learn and operate

Warehouse staff adapt quickly; everything is intuitive and clear without technical barriers.

A smarter warehouse management system, not just another tracking tool

- Full visibility of item movements – From receipt to dispatch, you know where each item is and who processed it.

- Process automation – Eliminates manual entries and paper documents, saving hours of work every day.

- Quick deployment and simple usage – Employees can work from day one, without technical background.

- Support that understands your operations – Direct communication with system authors means fast adjustments and support without waiting.

- Mobile app – Warehouse worker scans, confirms items, quantities and positions on an industrial terminal.

- Web application – Monitoring of documents and operators, item and location status, real-time reports.

- ERP integration – ERP sends documents to WMS; WMS returns confirmed quantities, locations and statuses — without double entry.

A proven warehouse management system that delivers results

Data accuracy

Automatic scanning and digital entry eliminate human error and inaccurate stock levels.

Faster processes

Receiving, issuing and inventory are performed multiple times faster — paperless, no waiting.

Lower costs

Digital data processing reduces costs and speeds up work.

Works with leading industrial terminals

Fast, precise and uninterrupted. Sensiteh WMS combined with industrial terminals ensures perfect control over every item.

I need a terminal recommendationFrequently asked questions

Bring order, accuracy and speed into warehouse processes

Every warehouse is different, so we adapt Sensiteh WMS to your processes. Send an inquiry to learn how to reduce errors and speed up deliveries.